100-percent American-made Bully Tools eyes expansions

Christopher Dacanay

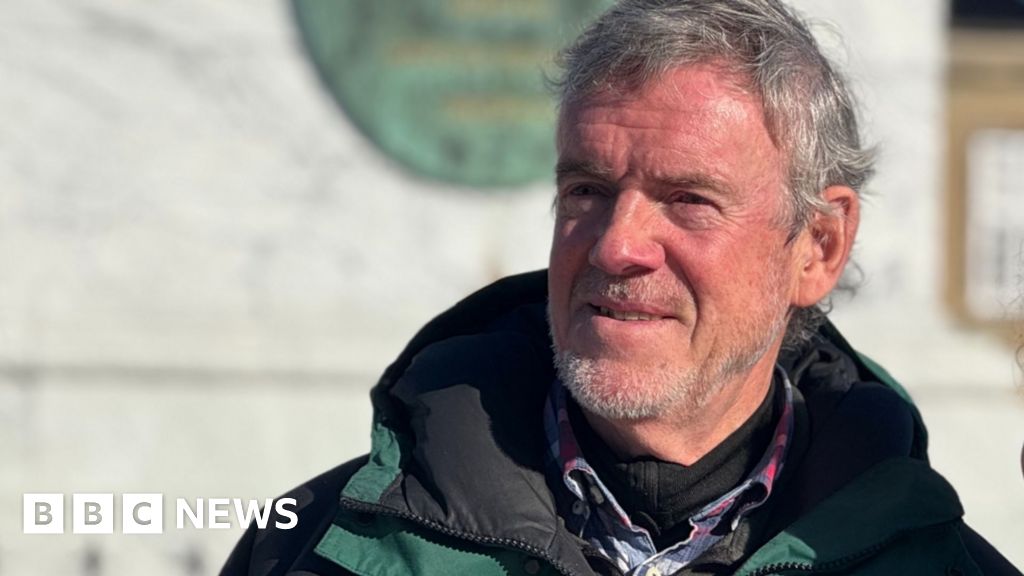

HANGING ON — Mark Gracy, president and founder of 100 Percent Made in the USA Bully Tools, hung from one of the company’s shovels to demonstrate its strength.

STEUBENVILLE — Bully Tools claims its purely American-made products are “Built to be Bullied.”

Doubtful? Mark Gracy, president and founder of the Steubenville-based tool manufacturer, would point toward Instagram, where the company has posted numerous videos supporting its assertion.

Clips depict tools being used and abused, though never losing their integrity. Products are run over by vehicles, used as pry bars and even hung on like monkey bars. It’s all to demonstrate their durability, which Gracy says far outpaces that of competitors’ products.

“All the things you’e not supposed to do with a shovel, we do, just to show we can do it,” Gracy said, not long before hanging — both feet off the ground — from a Bully Tools shovel suspended in the air by a forklift.

Increased marketing and advertising on Instagram and other online platforms is part of Bully Tools’ present shift toward a direct-to-consumer model.

The 30-year-old company isn’t abandoning retail, Gracy assured, but it is focusing more on direct-to-consumer sales. Bully Tools products can still be found in stores like Rural King and True Value, though they can also be purchased online through Amazon, Wal-Mart, Home Depot or BullyTools.com, Gracy said, adding that shipping is always free.

E-commerce now reportedly accounts for 50 percent of Bully Tools’ sales, compared to no percentage just five years ago when its own e-commerce platform first launched. Online sales have grown “dramatically,” while other sales also continue to grow, Gracy said.

Regardless of its sales model, Bully Tools will keep making 100 percent of its products in the USA, Gracy said. Specifically, manufacturing will occur at the company’s facility in the Jefferson County Industrial Park, which Gracy hopes to expand once the time is right.

Founded in 1994, Bully Tools prides itself in using American labor to manufacture 140 different products “for all seasons and people,” Gracy said. Those 140 different products include specialty tools and a complete line of long-handle tools — anything a farmer or gardener would need.

“I’m not sure if people realize it, but our official name is 100 Percent Made in the USA Bully Tools,” Gracy said. “It’s a long name, but it’s such a big aspect of what we do. … Every single ounce of every product is made in the USA. The vast majority of it is made in our factory. … There’s very little we don’t make here. The rest is made within 50 miles of here at local suppliers.”

The philosophy behind Bully Tools emerged decades ago, with Gracy spending summers with his grandfather, who owned a small farm in Meadville, Pa. Gracy’s grandfather would only buy Craftsman tools, knowing that if they ever broke, the company would replace them. That taught Gracy “If you buy quality, they’re good for life,” an idea he’d carry into his later entrepreneurship.

A building inspector in Pittsburgh at the time, Gracy decided to walk away from his job and start from scratch with his own business. He received abundant support from his wife and began producing a shingle remover, working out of a 1,500-square-foot space in Pittsburgh.

Slowly but surely, Gracy added more products and increased in-house manufacturing. Gracy was selling about 12 products — primarily through Home Depot — when he’d earned enough to upsize its facility.

In 2006, Gracy relocated his company to a spec building in the Jefferson County Industrial Park, enticed by incentives from the state like low-interest financing, which the company paid off in half the time. Bully Tools outfitted the structure to suit its needs and, after the Great Recession in 2008, began an expansion.

Bully Tools now produces nearly 12 times as many products as it did in 2006. The process is all-American, all the way through, from when coils of steel arrive in the facility until when they exit as fully formed tools.

The facility employs around 70 individuals, many of whom are directly involved in forming, assembling and shipping products. Although each tool requires its own unique set of steps, manufacturing processes may include robotic welding, heat treating, injection molding or powder coating.

Much of the tools’ soundness is due to proprietary information. Gracy said it generally comes from fiberglass handles’ specific resin and thickness, reinforcement of key leverage points, higher-grade steel and more rigid heat treating.

“Anybody can take our products and do that same test (like those on Instagram) to see how strong they actually are,” Gracy said. “It’s the materials we use and the designs, the engineering, that goes into it. Our competitors’ products just can’t hold up. … Seeing is believing with our products, and we have unconditional warranties on our products. We get very, very few returned products. … Nothing is indestructible, but you have to really try to break one of our shovels.”

Three years ago, Bully tools added another 20,000 square feet onto its existing 40,000 square-foot facility. The company now plans to add an additional 40,000 square feet to the second addition, which was built with expansion in mind.

That third addition — an 80 percent increase in space — would allow Bully Tools to add more products and perform more duties in house, Gracy said. Buildout is currently on hold until there’s a “good regulatory and governmental environment that’s conducive for expansion.”

Gracy said that a company’s ability to grow depends on cash flow. Additional capital, usually by way of profits and rolled back into additional labor and materials, allows companies to safely expand without the risk of bankruptcy. When that additional capital is disrupted through taxes or regulation, Gracy said, expansion prospects are hindered.

“I’m excited and looking to see if it happens, but under the new administration, they’re talking about ‘Made in the USA’ companies actually having a tax reduction. We’ll see if it goes through, but if it goes through, it’s going to jump-start ‘Made in the USA’ manufacturing and allow it to grow as well.”

Bully Tools is well-known in “Made in the USA” circles as the only company that successfully established a complete line of tools, rather than one or two individual tools, Gracy said.

The company’s reputation opened many doors, including those of the White House. Gracy has conferred with former President Donald Trump on two occasions. The first was when the now president elect had just taken office and was looking to showcase different U.S. products. On the second occasion, Gracy was asked to participate in a roundtable discussion regarding U.S. manufacturing issues.

Bully Tools products have been featured on the morning news and talk program “Fox & Friends.” The company’s shovel was named “The Best Shovel” by Wirecutter, a product recommendation service from the New York Times.

As Bully Tools enters 2025 — its 31st year in business — it’s holding fast to its “Made in America” foundation and respect for the Jefferson County facility it’s called home for nearly two decades.

“From day one,” Gracy said, “we’ve always made all of our products here, and we plan on continuing to do so.”

Related

U.S. economy adds jobs as federal layoffs and rising unemployment…

Julia Coronado: I think it's too early to say that the U.S. is heading to a recession. Certainly, we have seen the U.S. just continue t

The job listing site highlighting H-1B positions so Americans can…

A mysterious new job listings website recently went live, solely showing roles companies want to offer to their H-1B holders seeking Green Cards in an attempt t

Tepid February Jobs Report Boosts Odds of a June Fed…

Federal Reserve Board Chairman Jerome Powell speaks during a news conference. Photo by Chip ... [+] Somodevilla/Getty Images.Getty Images The February jobs repo

French university offers jobs to American scientists afraid of government…

As the current federal government in the U.S. has been freezing or cutting funding for several research grants, a French university has stepped in with an offer