New York

CNN

—

President Donald Trump’s plan to impose a 25% tariff on all imported aluminum could cost 100,000 American jobs, the CEO of one of the largest US aluminum makers warned on Tuesday.

The new tariff rate, a 15 percentage point increase from prior levels that doesn’t permit any exceptions or exemptions, is set to go into effect next month. It’s part of Trump’s aggressive strategy to beef up domestic manufacturing — but risks sparking a global trade war.

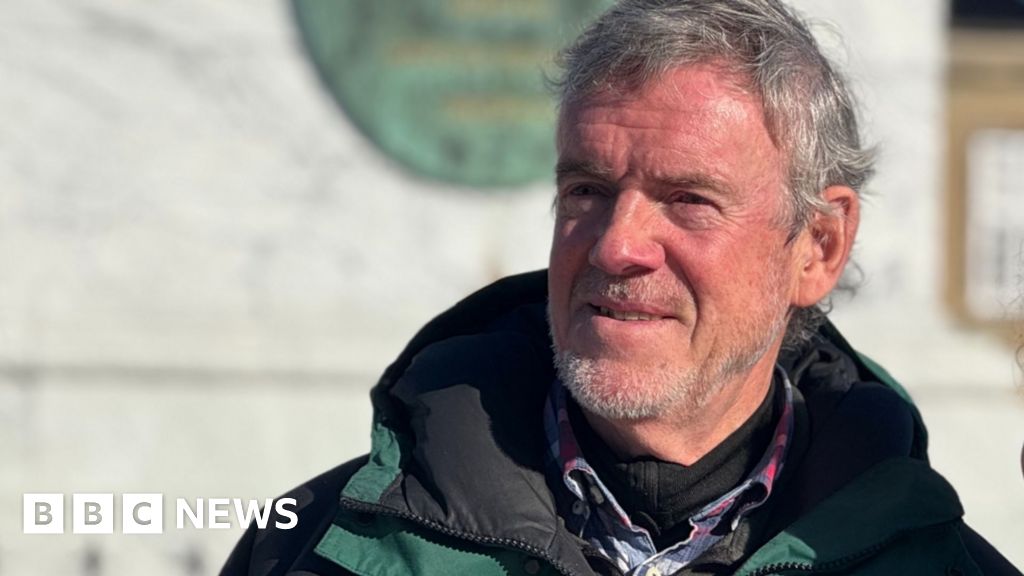

The tariffs would “destroy about 20,000 direct US aluminum industry jobs and could result in 80,000 indirect jobs being eliminated in the US,” said William Oplinger, CEO of Alcoa, speaking at the BMO Global Metals and Mining conference. “It’s bad for the US,” he added.

In total, the aluminum industry directly employs 164,000 workers in the US and indirectly employs an additional 272,000 workers within industries such as mining, construction and manufacturing, according to the Aluminum Association.

Though Alcoa is headquartered in Pittsburgh, a significant share of Alcoa’s aluminum production is located in Canada and then shipped to the US, Oplinger said.

That, in addition to the negative consequences US consumers could face from the aluminum tariff, is why he said the company is lobbying the Trump administration to “at a minimum” enact an exemption on Canadian metal exports to the US, allowing for two-thirds to enter the country duty-free.

Coca-Cola CEO James Quincey said this month the company is preparing to package more of its products in plastic and glass as opposed to aluminum to avoid the higher input costs if the tariffs go into effect. If that shift happens, it could lead to job losses at canning facilities Coca-Cola works with.

“International companies have long undercut American aluminum production by flooding the US market with cheap imports from countries like Australia, Brazil and Canada,” White House spokesman Kush Desai told CNN. “Although disruptive to these companies’ business models, President Trump’s tariffs are necessary to safeguard America’s national security and economic interests by onshoring critical aluminum production.”

Canada, the top source of aluminum imported by the US, shipped $11 billion worth of raw aluminum and goods containing a significant amount of aluminum to the US last year, according to Commerce Department data. In total, the US imported $27 billion worth of aluminum last year, which also came from trading partners like China, Mexico, the United Arab Emirates and South Korea. Meanwhile, the US exported $14 billion worth of aluminum across the globe.

The US largely relies on foreign aluminum because countries like Canada have relatively lower energy costs to produce it, according to a 2022 report published by the nonpartisan Congressional Research Service.

Alcoa estimates that a 25% tariff on Canadian aluminum shipped to the US would cost US customers an additional $1.5 billion to $2 billion annually, Oplinger said on the company’s earnings call last month.

Generally, tariffs imposed on other nations’ imports can negatively impact domestic consumers, resulting in higher prices for the goods. An additional concern is that other countries could retaliate against the US by imposing tariffs on its exports. The reduction in demand could force companies to lay off workers.

For instance, when the Trump administration put tariffs of 25% on steel and 10% on aluminum in place in 2018, it briefly cut imports and increased domestic production. But many customers of imported steel and aluminum still found it necessary to import those goods from lower-priced producers elsewhere. Those actions also ignited a trade war that hit American goods with retaliatory tariffs that raised prices on other items for consumers.

Bernd Lange, chair of the European Parliament’s trade committee, recently said it would respond to pending aluminum and steel tariffs by levying tariffs on American goods including motorcycles, jeans, peanut butter, bourbon and whiskey.

Alcoa has some untapped domestic production capacity, but it’s “very old, very inefficient capacity that has not been run in a number of years,” Oplinger said. Nevertheless, the company will be assessing whether it makes financial sense to invest in upgrading the domestic facilities to avoid tariffs.

But it’s a tough call, said Oplinger, who became Alcoa’s CEO in 2023. “One of the issues around the uncertainty of the tariffs is it’s very hard to make an investment decision even on something like a restart without knowing how long the tariffs will last.”

“More broadly, the administration has asked us, are we likely to reshore aluminum production in the United States? We make decisions around aluminum production that are a horizon of 20 to 40 years,” he said. “We would not be making an investment in the United States based on a tariff structure that could be in place for a much shorter period of time.”