WATCH NOW ONLINE: See U.S. Rep. Morgan Griffith, R-9th, touring the American Merchant facility Tuesday morning, May 28, with plant Manager David Ortega.

BRISTOL, Va. — A local towel manufacturer recently added a weekend shift while continuing to try and expand its footprint in a competitive, international landscape.

American Merchant, which began operating at the former Ball Manufacturing plant in December 2019, survived slow periods during the COVID-19 pandemic and recently added a weekend manufacturing shift at its 260,000 square-foot facility on Old Abingdon Highway.

American Merchant, which has retail sales arrangements through Belk and other firms, bills itself as making the “softest, most luxurious bath towels in America.”

They produce different lines of “classic American towel”; all are strong, absorbent, anti-microbial towels that are durable and don’t shrink, company President Maxwell Bleakie said.

“[Former owner] Ball was very responsible, and the plant was almost turn-key ready … We had been all through Alabama, North Carolina looking for plants,” Bleakie said, adding they closed plants in China to move to Bristol.

People are also reading…

“China became too expensive, and a lot of that business was all going down to Vietnam and Bangladesh. We decided to sell that piece of property and invest in ‘Made in America.’ The first towels went out of here in January 2020,” he said.

There is currently one other domestic towel manufacturer now in operation after Georgia-based 1888 Mills closed last month, Bleakie said in response to a question.

Former Virginia Gov. Terry McAuliffe brought the project to Southwest Virginia. Then the company spent nearly two years acquiring, installing and activating more than $20 million in state-of-the-art manufacturing equipment to produce towels and wash cloths.

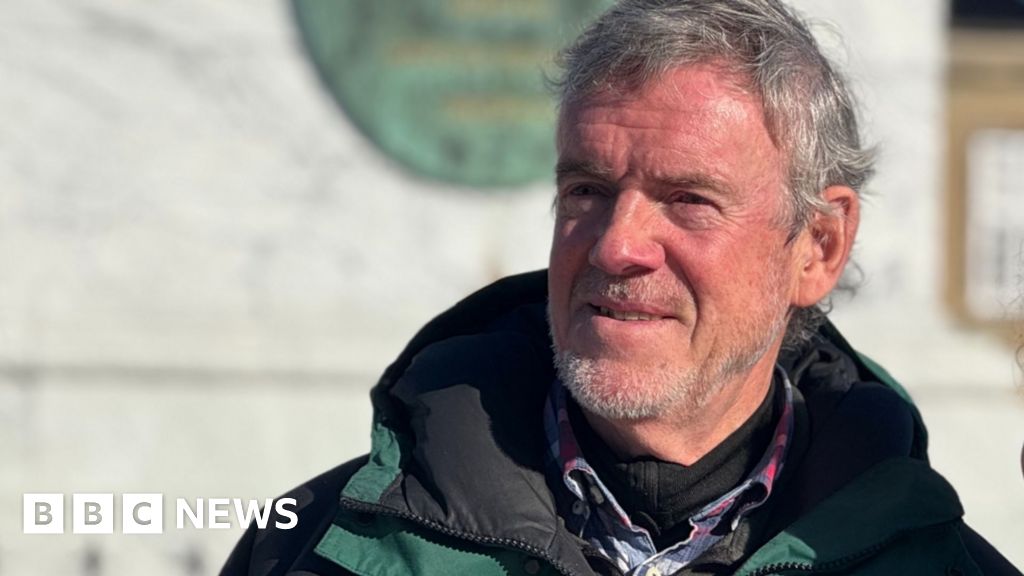

U.S. Rep. Morgan Griffith, R-9th, toured the facility Tuesday morning and learned more about its operations.

“It’s good to see American products being made in the United States of America. A lot of times people go to the store and they’re just looking at prices. They’re not looking at the fact maybe their neighbor down the street helped make these towels and should be looking for that made in America logo,” Griffith said. “They’re one of two in the country, so there’s a good chance, if you buy that, you’re buying from right here in Bristol.”

The firm buys only U.S.-produced cotton yarn for its towel products, Griffith said.

“It helps us, as a community, to have jobs like this and facilities like this that buy the yarns, the chemicals and other products in our backyard,” Griffith said.

Competing is challenging, Bleakie said.

“It’s hard because, if you’re buying from overseas, you have lower labor rates and the overseas government that is subsidizing the export. So for every towel that goes out of India or Pakistan, those manufacturers are getting an extra 5% or 10% from the government in subsidies,” Bleakie said.

The plant currently employs over 50 workers and primarily operates Mondays through Thursdays.

“We’ve seen our business increase over the last year and we’ve started a weekend shift,” plant Manager David Ortega said.

Bleakie said they are presently growing their direct sales to consumers.

“We strongly believe in E-commerce so we can sell directly to the customer and fulfill each order right out of the warehouse,” Bleakie said. “We did a program with HSN [Home Shopping Network] and we’re pitching them again. The business we have now is all with a New York importer so we also hope to have more direct connection with the retailer. We’re making samples for Sam’s Club, for example.

“Television marketing is the perfect way to tell the story about made in America and to talk about the quality,” he said.

Twitter: @DMcGeeBHC